Generator Maintenance ETQ3000

Its remarkable how far general maintenance can bring an engine. I purchased this ETQ TG 3000W generator from Kijiji for $50, as the owner said it was non-operational and hasn’t started in years. From not starting to starting on the first pull, today we’ll go over the general maintenance steps that keep any small air-cooled gasoline generator running in peak shape.

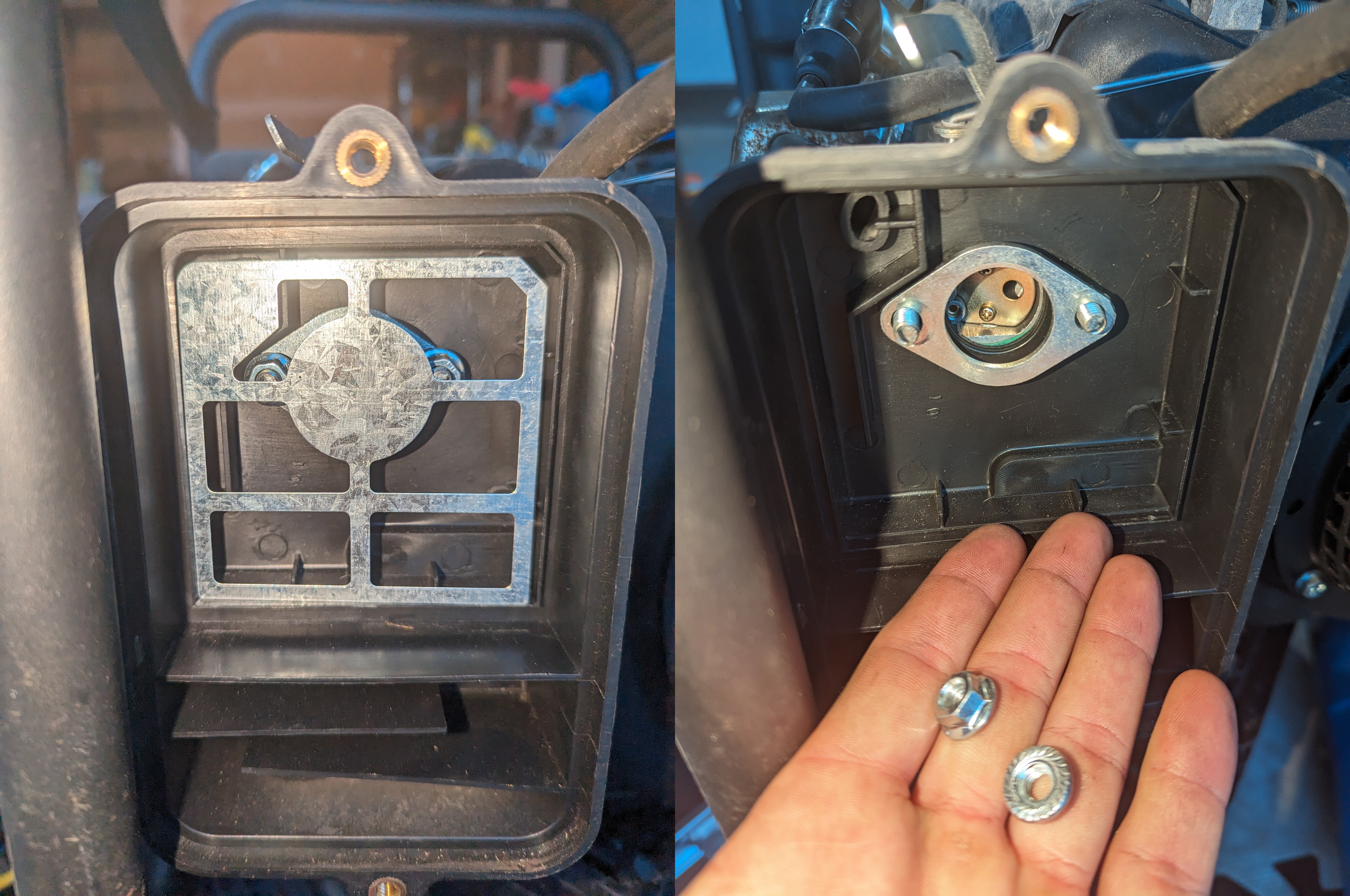

Air Filter

I realize I dont have a photo of the Air Filter… oops! Upon disengaging the air cleaner cover, accessing the air filter becomes straightforward. Employing either an air compressor or gentle tapping effectively dislodges any sizable or loose debris from the filter. Assuming the filter is reusable, (foam or fabric) additional cleaning can be performed by immersing it in a mild detergent or soap solution, or by utilizing specialty filter oils.

I realize I dont have a photo of the Air Filter… oops! Upon disengaging the air cleaner cover, accessing the air filter becomes straightforward. Employing either an air compressor or gentle tapping effectively dislodges any sizable or loose debris from the filter. Assuming the filter is reusable, (foam or fabric) additional cleaning can be performed by immersing it in a mild detergent or soap solution, or by utilizing specialty filter oils.

Ensure Air filter is thoroughly dried before running the generator again

Carburetor

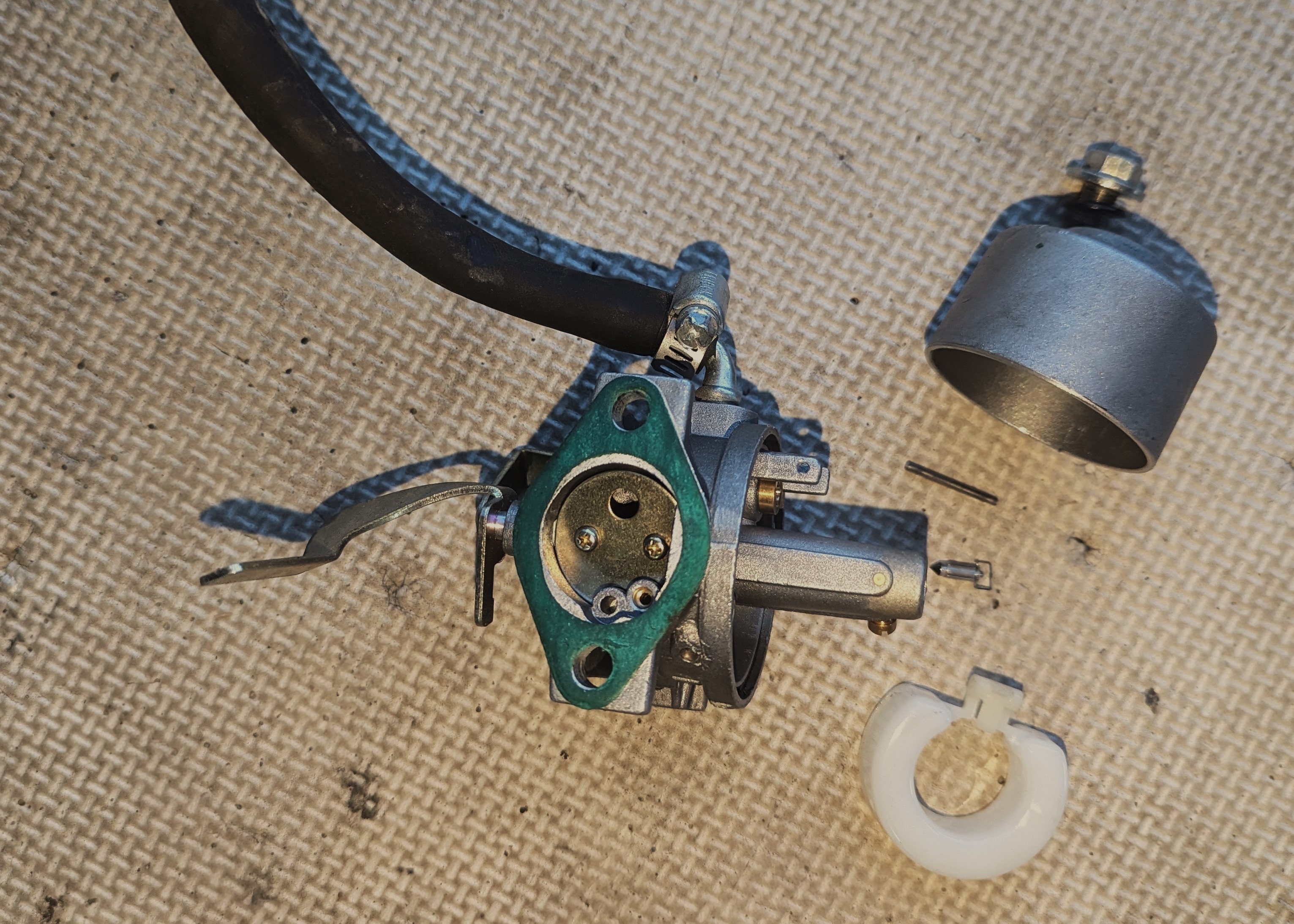

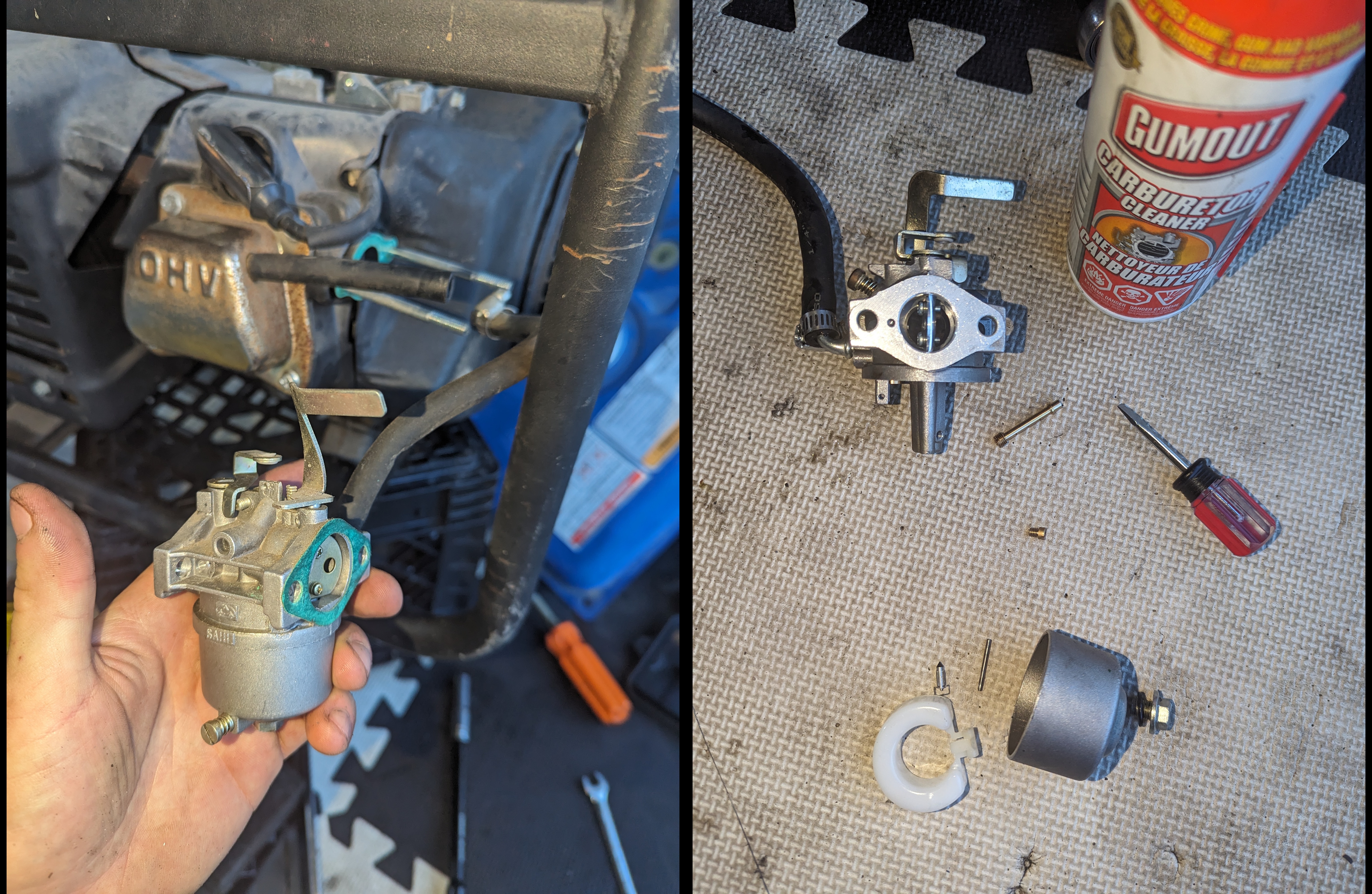

Carburetor The carburetor, mounted behind the air cleaner cover, demands extra attention due to its intricate makeup and components. Cleaning this vital part is crucial for maintaining optimal engine performance, as it ensures the proper mixture of air and fuel for combustion. Over time, interior passages and jets can become clogged with dirt, debris, or other buildup, leading to engine issues. To effectively clean these components, I prefer using carburetor cleaner along with a thin guitar string to access narrow passages and jets. During the cleaning process, it’s important to carefully inspect all parts for any signs of damage or wear. Replace any damaged gaskets or seals to prevent leaks and ensure a proper seal.

Carburetor The carburetor, mounted behind the air cleaner cover, demands extra attention due to its intricate makeup and components. Cleaning this vital part is crucial for maintaining optimal engine performance, as it ensures the proper mixture of air and fuel for combustion. Over time, interior passages and jets can become clogged with dirt, debris, or other buildup, leading to engine issues. To effectively clean these components, I prefer using carburetor cleaner along with a thin guitar string to access narrow passages and jets. During the cleaning process, it’s important to carefully inspect all parts for any signs of damage or wear. Replace any damaged gaskets or seals to prevent leaks and ensure a proper seal.

Check that any solvents or cleaning chemicals used on the float are compatible with plastic

Spark Plug

Spark Plug On this model the spark plug is accessible without removing any other components. To ensure proper ignition and efficient combustion, cleaning or replacing the spark plug is essential. Utilizing sandpaper and a wire brush effectively removes any soot buildup on the spark plug. A feeler gauge is then used to verify and adjust the gap to the correct specification, ensuring reliable spark ignition.

Spark Plug On this model the spark plug is accessible without removing any other components. To ensure proper ignition and efficient combustion, cleaning or replacing the spark plug is essential. Utilizing sandpaper and a wire brush effectively removes any soot buildup on the spark plug. A feeler gauge is then used to verify and adjust the gap to the correct specification, ensuring reliable spark ignition.

Oil Change

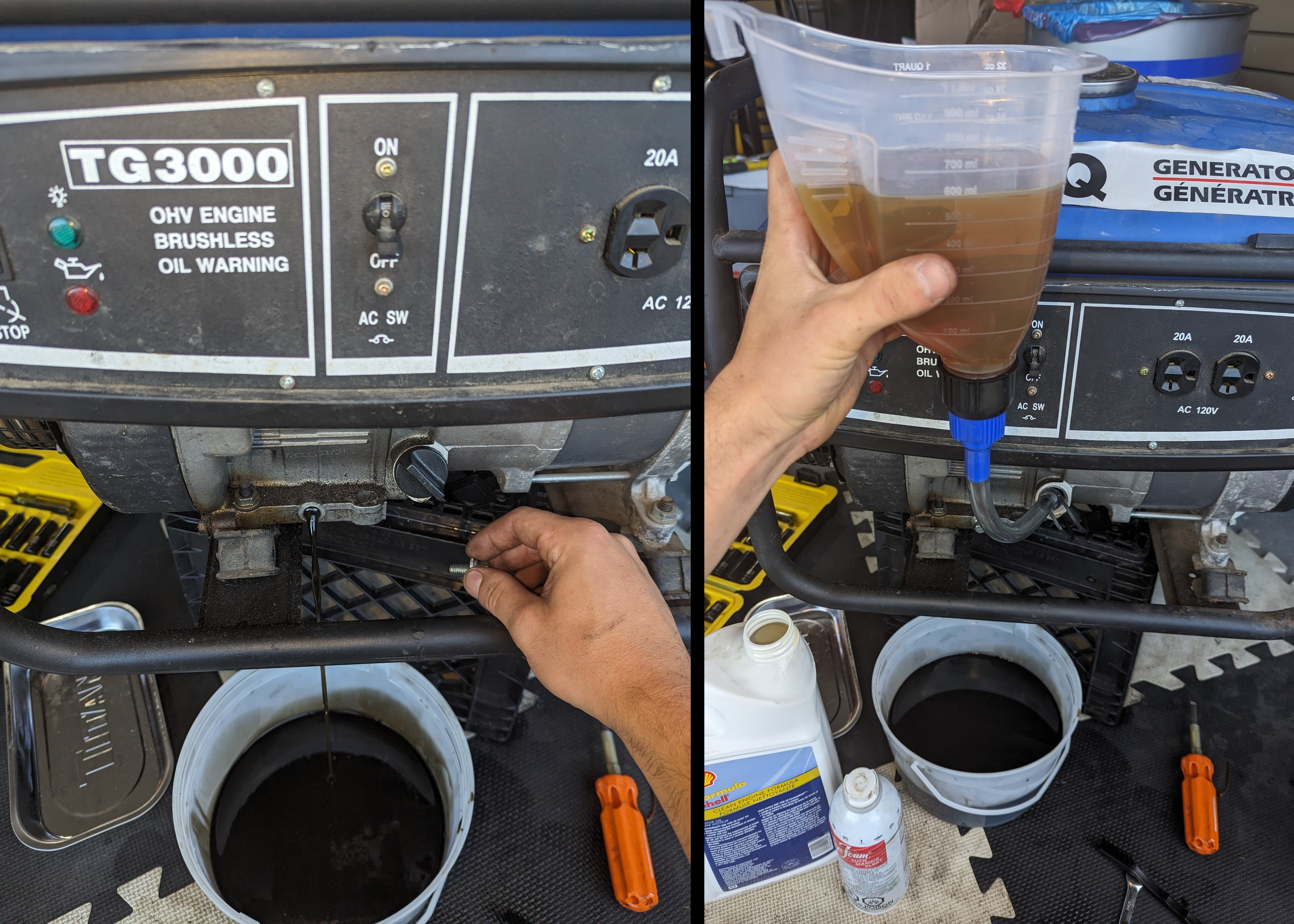

Oil Change Since many small generators lack an oil filter, performing an oil change is usually a straightforward process. Simply drain the old oil and refill it with the appropriate amount of fresh oil according to the owner’s manual specifications. I opt for 0.6L of Shell Rotella 10W-30 in this case as it ensures optimal engine performance, even in temperatures as low as -30C.

Oil Change Since many small generators lack an oil filter, performing an oil change is usually a straightforward process. Simply drain the old oil and refill it with the appropriate amount of fresh oil according to the owner’s manual specifications. I opt for 0.6L of Shell Rotella 10W-30 in this case as it ensures optimal engine performance, even in temperatures as low as -30C.